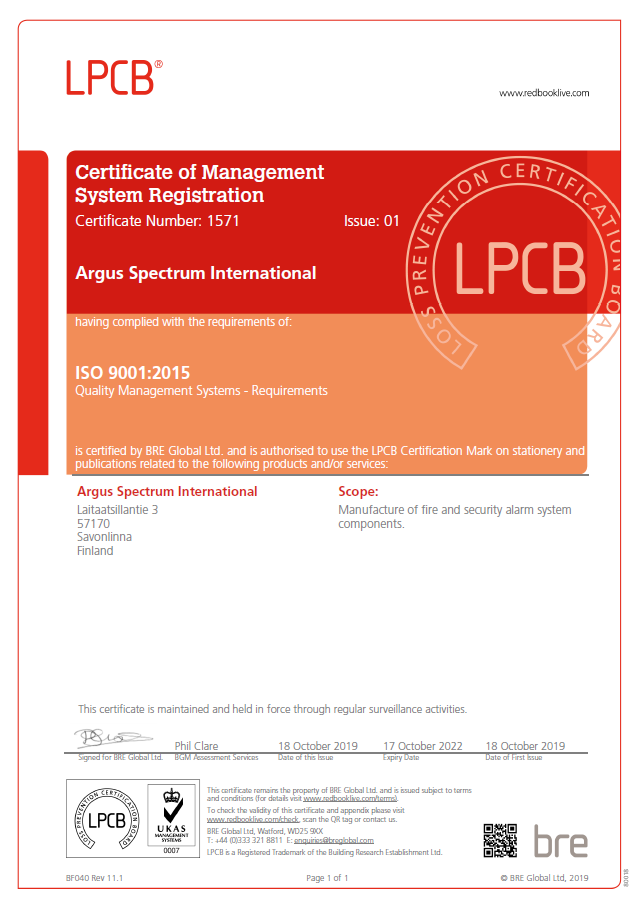

Week commencing 18th October 2021 saw yet another audit of the ASI manufacturing facility at Savonlinna (Finland) by BRE Global / LPCB. This is the fifth audit to take place since receiving our ISO 9001:2015 certificate in October 2019. Since then the Finnish production facility has been audited twice a year but now is switched to a once-a-year audit regime ahead of schedule.

The team are immensely proud of our record of zero non-conformities being identified during this audit. ASI are a proactive organisation constantly looking for ways to improve and as such welcome the opportunity for their world class facilities to be audited by external approval organisations such as LPCB.

DOWNLOAD

Developed in 1984 the ISO 9001 standard is defined as the international standard that specifies requirements for a quality management system (QMS). A company that complies with the standard adheres to certain rules and regulations in the organisation of technological and business processes, what guarantee the high quality of its products.

The LPCB audit has confirmed one more time that the quality management system at the ASI complies with all the principles on which the ISO 9001:2015 standard is based:

- constant control over the quality of the goods produced;

- continuing professional development of employees;

- regular updating of production in terms of technical and technological processes used;

- extensive use of modern information technologies and software;

- interaction with consumers of goods and services, including prompt response to incoming complaints and suggestions;

- building relations with business partners and suppliers as transparently as possible and based on fair and mutually beneficial contracts;

- continuous improvement of management methods by using modern tools that facilitate management automation.

About ASI production in Finland

In 2019 the ASI opened a manufacturing facility in Finland. As part of the preparation of the production site were launching two surface mounting lines, training employees and producing pilot batches. The Savonlinna factory contains a testing laboratory conforming to EN54 standards. The laboratory is fully equipped with all the necessary facilities for fire detection testing - certified smoke and heat test tunnel, acoustic anechoic chamber, light camera, radiochannel and mechanical test rigs. Concurrently with opening of the plant, the equipment was being certified to requirements of European Certification Board. The radio system was confirmed for compliance to EN 54 standard by IMQ (Italy) and later by LPCB (Great Britain).

With the launch of its own production site in the European Union and through partnerships with a number of international companies, ASI plans to enter new highly competitive markets and secure growth in export revenues by increasing deliveries of radio channel equipment to Europe and the Middle East. The total investment in production in Finland has amounted to 3 million euros. In the future the design capacity of the Finnish plant is planned to reach 50 million euros per year.